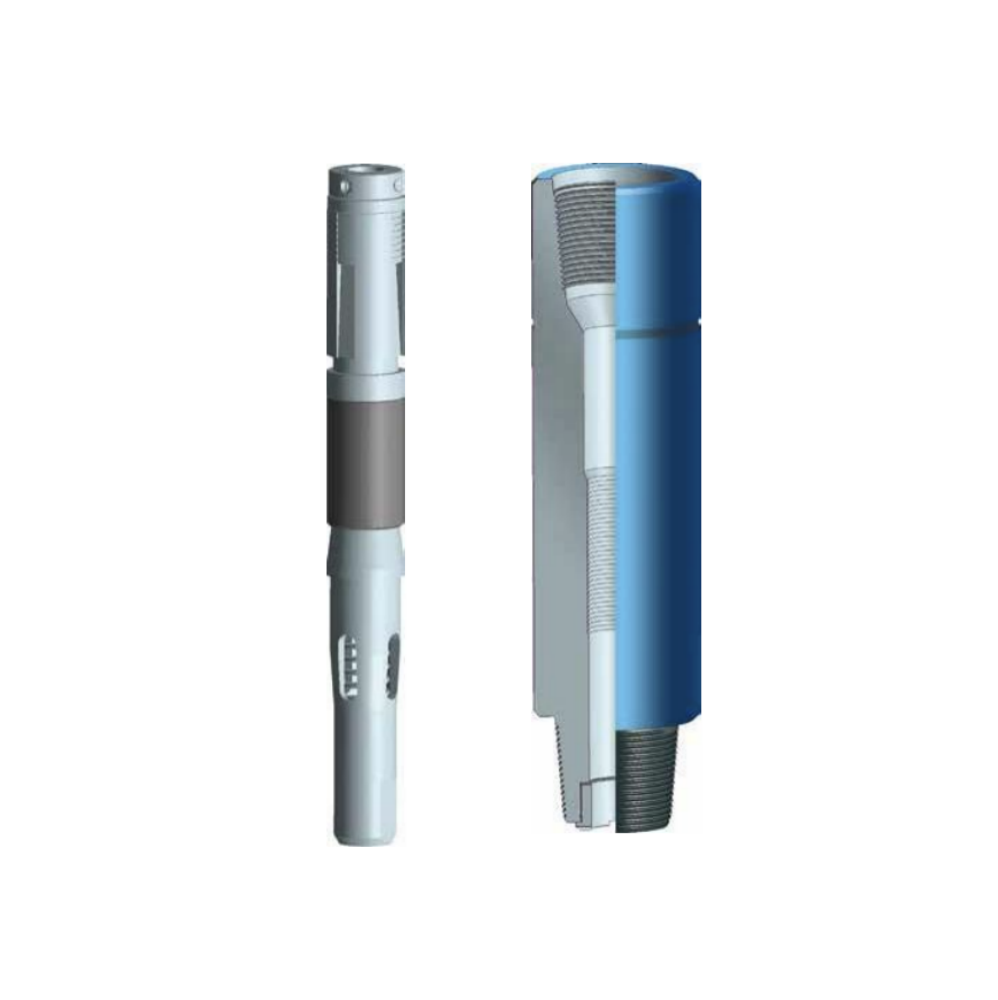

Drop-In Check valves prevent return flow during a kick and are suitable for most drilling situations in which return flow through the drill string is a risk and normal operation requires the benefits of a full-bore sub. By preventing upward flow through the drill pipe and allowing fluid to be pumped downward to circulate the well, the valves provide the driller with the means to control the drill pipe pressures when required, significantly improving and simplifying well control.

The multiple activation by-pass valve is a set of short circuit that can be opened and closed for many times. It is generally installed in special drilling tool assemblies such as directional drilling, speed raising, logging while drilling, etc. It can open and close the bypass hole in time for special operations according to downhole working conditions, enhance the applicability of special drilling tool assemblies, improve production efficiency, and reduce well control risks.

The non-rotating casing scraper is one of the indispensable auxiliary tools for well completion, testing and downhole operations. Its main purpose is to remove cement, sand, scratches, paraffin, burrs and other attachments on the inner wall of the downhole casing, protect the cleanness of the inner wall of the casing, and facilitate the normal operation of all drilling tools.

Kelly valve is a manually operated ball type valve for the drill stem, divided into upper and lower sections. The upper Kelly valve is connected between lower end of swivel and upper end of Kelly. The lower Kelly valve is connected between upper end of drill pipe and lower end of Kelly or lower end of Kelly saver subs. The Kelly valve can be opened or closed off by simply turning a special operating wrench 90° according to indicated direction.

Full Opening Safety valve (FOSv) is a ball type safety valve used to stop flow through the drill string when the drill string is being withdrawn from the well.

Drop-In Check valves prevent return flow during a kick and are suitable for most drilling situations in which return flow through the drill string is a risk and normal operation requires the benefits of a full-bore sub. By preventing upward flow through the drill pipe and allowing fluid to be pumped downward to circulate the well, the valves provide the driller with the means to control the drill pipe pressures when required, significantly improving and simplifying well control.