QY type Hydraulic Drilling Yar

QY type hydraulic drilling jar is a new generation of double-acting hydraulic jar that is fully upgraded by our company on the basis of the original QYSZ Ⅱ type full-hydraulic drilling jar. It has the characteristics of simple operation, adjustable shock tonnage, high temperature resistance, etc. This type of drilling jar adopts a new hydraulic delay release system, which has excellent reliability and wide adaptability.

Related products

Tianhe Downhole motor design d on the most advanced international design technology. We have a Closely cooperating with domestic, surgical research institutes, universities and oilfield drilling companies, and through careful research and development of R & D center in Canada, the design of technical parameters and structure can meet the most demanding oil drilling needs. Tianhe downhole motor is designed for durability and longer service life for different use conditions, with the most stringent specific tolerances for design and manufacturing standards.

The common drill pipe is a rod that connects the drill bit, delivers the drilling fluid and transmits the power in the drilling tool. Our common drill pipe conforms to SY/T5561 and API Spec5DP standards. In order to reduce the wear of the casing and drill pipe, we can weld the wear belt at the end of the drill pipe female buckle joint. Our company has obtained the production and use license of ARNCO 100XT, ARNCO 150XT, ARNCO 300XT and ARNCO 350XT authorized by the American Anke company.

The agitator can improve the effectiveness of bit weight transfer and reduce the friction between drilling tool and borehole through the longitudinal vibration produced by the hydraulic action of drilling fluid, especially in the process of directional drilling to improve the bit weight transfer and reduce torsional vibration. It is a downhole tool used to solve downhole depressurization and improve weight on bit transfer. Smooth weight on bit transfer improves the ability to adjust the bit toolface to reach further target zones. It does not require too much work to adjust the tool face during drilling, keeping the tool face stable and increasing ROP. Particularly suited for horizontal, extended-reach Wells, it can be used in conjunction with MWD, screw, and any bit.

Application

It is suitable for all conventional wells, inclined wells and large displacement wells at all temperatures not higher than 160℃ .

Features

The superior machine structure is to further improve the machine maintainability.

The better sealing materials are selected to improve the reliability of sealing

The core mechanism adopts the seal oil bath design to reduce the wear and tear of the moving parts and improve the life of the whole machine.

The overflow area of the release channel is increased to reduce the running resistance and greatly improve the shock effect.

The operating force of hydraulic releasing mechanism can be controlled on the ground by driller, and can be flexibly adjusted according to the downhole situation.

The optional mechanical locking module is added to meet the needs of some special users. Increase the fast recovery function of the upward and downward strokes.

The mandrel moves back to the middle position, and then the jar will do jarring again in either of the two directions.

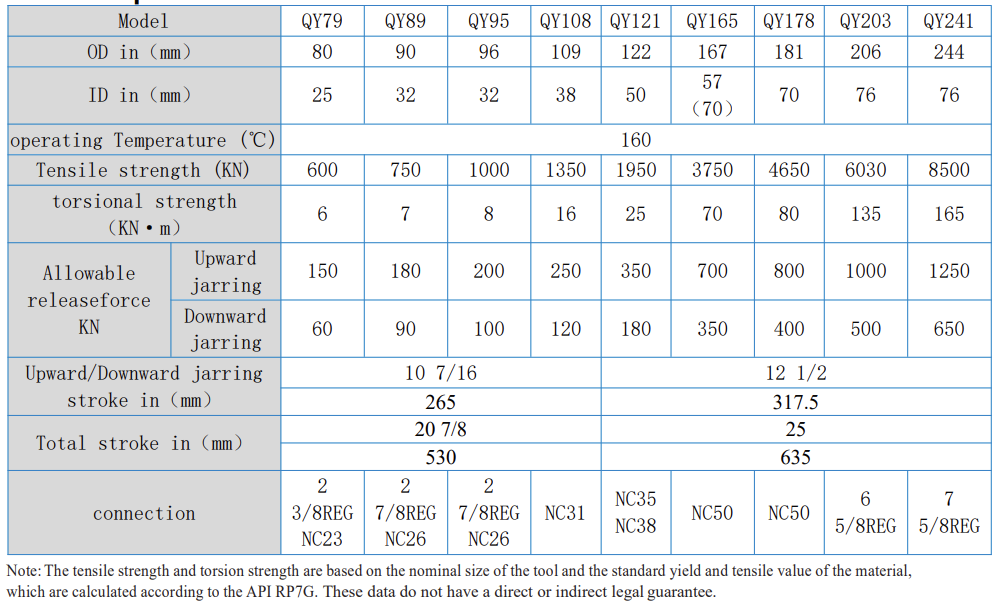

Technical parameters table