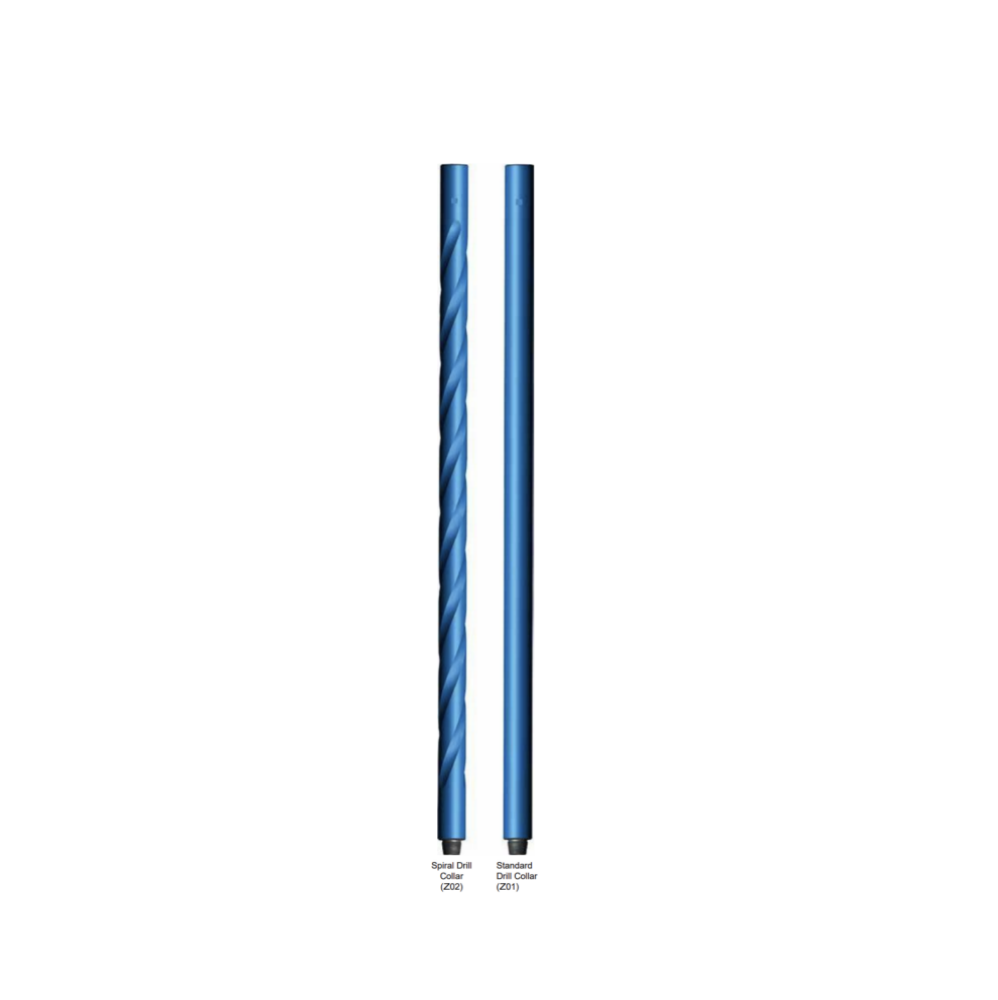

Drill Collar-Standard And Spiral

Drill Collar is the basic component in the BHA which provides weight on the bit for drilling and keeps the drill string in tension.

TIANHE Drill Collar is manufactured from AISI 4145H modified quenched and tempered steel and is heat treated along its entire length for uniform toughness and durability. Strict metallurgical tests are performed per specifications to ensure that the heat treatment produces consistent and maximum hardness through the depth of the bar.

Related products

Tianhe Downhole motor design d on the most advanced international design technology. We have a Closely cooperating with domestic, surgical research institutes, universities and oilfield drilling companies, and through careful research and development of R & D center in Canada, the design of technical parameters and structure can meet the most demanding oil drilling needs. Tianhe downhole motor is designed for durability and longer service life for different use conditions, with the most stringent specific tolerances for design and manufacturing standards.

The common drill pipe is a rod that connects the drill bit, delivers the drilling fluid and transmits the power in the drilling tool. Our common drill pipe conforms to SY/T5561 and API Spec5DP standards. In order to reduce the wear of the casing and drill pipe, we can weld the wear belt at the end of the drill pipe female buckle joint. Our company has obtained the production and use license of ARNCO 100XT, ARNCO 150XT, ARNCO 300XT and ARNCO 350XT authorized by the American Anke company.

The agitator can improve the effectiveness of bit weight transfer and reduce the friction between drilling tool and borehole through the longitudinal vibration produced by the hydraulic action of drilling fluid, especially in the process of directional drilling to improve the bit weight transfer and reduce torsional vibration. It is a downhole tool used to solve downhole depressurization and improve weight on bit transfer. Smooth weight on bit transfer improves the ability to adjust the bit toolface to reach further target zones. It does not require too much work to adjust the tool face during drilling, keeping the tool face stable and increasing ROP. Particularly suited for horizontal, extended-reach Wells, it can be used in conjunction with MWD, screw, and any bit.

Features and Benefits

● A hardness range of 285 to 341 BH N and a Charpy impact value of 40 lbs/ft are guaranteed for evenly distributed 16 points in any cross sections at room temperature;

● Connections are phosphate coated after machining to protect the threads from corrosive elements and to prevent galling upon initial make-up;

● Thread roots are cold rolled on API and H-90 connections;

● Pressed steel thread protectors are supplied for all drill collar that are equipped with standard connections

When ordering please specify:

● Drill collar OD and ID;

● Overall length;

● Connections required (size and type);

● Special features desired, for example: Slick or Spiral; Stress Relief Features; Slip and/or Elevator Recess; Hardbanding;